How Industrial IoT is Reinventing Supply Chain Visibility

Discover how Industrial IoT transforms supply chain visibility with real-time tracking, RFID sensors, and predictive analytics for smarter operations.

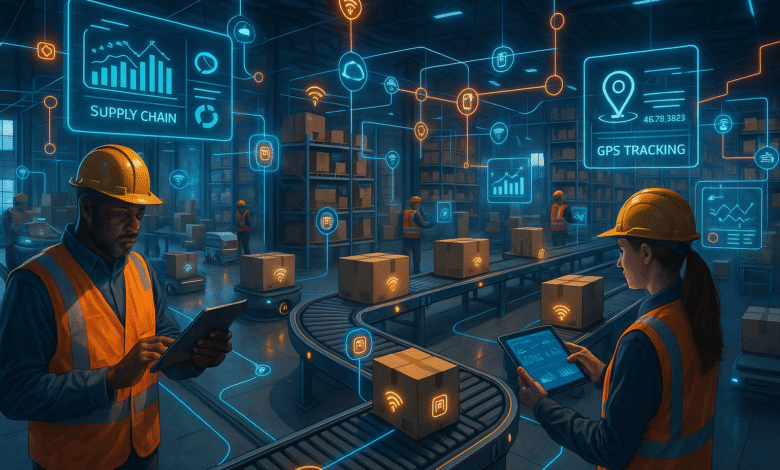

The modern supply chain landscape has undergone a dramatic transformation, driven largely by the rapid adoption of Industrial IoT (IIoT) technologies. Traditional supply chain management, once characterized by limited visibility and reactive decision-making, is evolving into a connected, intelligent ecosystem where every asset, shipment, and process can be monitored in real-time.

Industrial IoT represents the convergence of physical assets with digital intelligence, creating unprecedented opportunities for supply chain visibility. By integrating sensors, RFID tags, GPS trackers, and advanced analytics platforms, companies can now track goods from raw material sourcing through final delivery with remarkable precision. This technological revolution addresses one of supply chain management’s most persistent challenges: the lack of end-to-end visibility that often leads to inefficiencies, delays, and increased costs.

Today’s supply chain managers are no longer operating in the dark. They have access to continuous streams of real-time data that enable proactive decision-making, predictive maintenance, and optimized operations. The Industrial IoT ecosystem is fundamentally changing how businesses approach inventory management, quality control, and customer satisfaction, creating more resilient and responsive supply chains than ever before.

Understanding Industrial IoT in Supply Chain Context

What Makes Industrial IoT Different

Industrial IoT distinguishes itself from consumer IoT through its focus on industrial-grade reliability, security, and performance. In supply chain applications, IIoT encompasses a network of interconnected devices including smart sensors, RFID tags, GPS trackers, and edge computing devices that collect, process, and transmit data throughout the supply chain ecosystem.

The core components of an Industrial IoT supply chain system include:

- Sensor Networks: Temperature, humidity, vibration, and shock sensors that monitor product conditions

- RFID Technology: Radio-frequency identification tags that enable automatic product identification and tracking

- GPS Tracking Systems: Location-based services that provide real-time positioning data

- Edge Computing Devices: Local processing units that analyze data at the point of collection

- Cloud Platforms: Centralized systems that aggregate and analyze data from multiple sources

The Evolution from Supply Chain 3.0 to Supply Chain 4.0

The transition to Supply Chain 4.0 represents a fundamental shift from traditional linear processes to interconnected, intelligent networks. While previous generations relied on manual processes and limited automation, Supply Chain 4.0 leverages Industrial IoT, artificial intelligence, and predictive analytics to create self-optimizing systems.

Key characteristics of this evolution include:

- Real-time data collection and analysis

- Predictive rather than reactive maintenance

- Automated decision-making processes

- Enhanced collaboration between supply chain partners

- Improved risk management and compliance monitoring

Real-Time Tracking and Monitoring Capabilities

GPS and Location Intelligence

Real-time tracking through GPS technology has become a cornerstone of modern supply chain management. Advanced GPS tracking systems provide continuous location updates for vehicles, containers, and individual shipments, enabling supply chain managers to monitor progress and respond quickly to disruptions.

Modern GPS tracking solutions offer several advantages:

- Precise Location Data: Sub-meter accuracy for critical shipments

- Route Optimization: Dynamic routing based on traffic, weather, and delivery priorities

- Geofencing Capabilities: Automated alerts when shipments enter or exit designated areas

- Historical Analytics: Route performance analysis for continuous improvement

Companies like FedEx and UPS have revolutionized package delivery through sophisticated GPS tracking networks that provide customers with precise delivery windows and real-time status updates.

RFID Technology Integration

RFID technology serves as the backbone of many Industrial IoT supply chain implementations. Unlike traditional barcoding systems, RFID tags can be read automatically without line-of-sight scanning, enabling continuous monitoring of inventory movements.

The benefits of RFID integration include:

- Automatic Inventory Updates: Real-time stock level monitoring without manual scanning

- Reduced Human Error: Elimination of manual data entry mistakes

- Bulk Reading Capabilities: Simultaneous scanning of multiple items

- Enhanced Security: Anti-theft and tamper detection features

Walmart has successfully implemented RFID across its supply chain, resulting in 95% inventory accuracy and significant reductions in out-of-stock situations.

Sensor-Based Condition Monitoring

IoT sensors enable unprecedented visibility into product conditions throughout the supply chain journey. Temperature-sensitive products like pharmaceuticals and fresh foods require constant monitoring to maintain quality and compliance with regulatory standards.

Critical monitoring parameters include:

- Temperature Control: Maintaining cold chain integrity for perishable goods

- Humidity Levels: Preventing moisture damage to sensitive products

- Shock and Vibration: Detecting potential damage to fragile items

- Light Exposure: Protecting photosensitive materials

Predictive Analytics and Smart Decision Making

Data-Driven Insights

The combination of Industrial IoT data collection with predictive analytics creates powerful decision-making capabilities. Machine learning algorithms analyze historical patterns, current conditions, and external factors to predict potential disruptions and optimization opportunities.

Key applications of predictive analytics include:

- Demand Forecasting: Improved accuracy in predicting customer demand

- Inventory Optimization: Automated reordering based on consumption patterns

- Maintenance Scheduling: Predictive maintenance to prevent equipment failures

- Risk Assessment: Early warning systems for potential supply chain disruptions

Machine Learning Integration

Advanced machine learning algorithms process vast amounts of IoT sensor data to identify patterns and trends that human analysts might miss. These systems continuously learn and improve their predictions, creating increasingly accurate forecasts over time.

Amazon’s use of predictive analytics has enabled “anticipatory shipping,” where products are moved closer to customers before orders are actually placed, reducing delivery times and improving customer satisfaction.

Industry-Specific Applications

Healthcare and Pharmaceutical Supply Chains

The healthcare industry relies heavily on Industrial IoT for maintaining product integrity and regulatory compliance. Cold chain monitoring is critical for vaccines, biologics, and other temperature-sensitive medications.

Key applications include:

- Temperature Monitoring: Continuous tracking of refrigerated medications

- Chain of Custody: Complete audit trails for controlled substances

- Expiration Date Management: Automated alerts for products approaching expiration

- Regulatory Compliance: Documentation for FDA and other regulatory requirements

Food and Beverage Industry

Food safety and traceability are paramount concerns in the food and beverage industry. Industrial IoT solutions enable end-to-end tracking from farm to table, ensuring product quality and enabling rapid response to contamination issues.

Applications include:

- Farm-to-Fork Traceability: Complete product journey documentation

- Quality Assurance: Real-time monitoring of storage and transport conditions

- Recall Management: Rapid identification and isolation of affected products

- Compliance Monitoring: Adherence to food safety regulations

Automotive Manufacturing

The automotive industry uses Industrial IoT for both component tracking and fleet management. Complex supply chains require precise coordination of thousands of components from multiple suppliers.

Key implementations include:

- Just-in-Time Delivery: Precise timing of component deliveries to assembly lines

- Quality Control: Tracking component history and performance

- Supplier Management: Real-time visibility into supplier performance

- Warranty Tracking: Component-level traceability for warranty claims

Technology Integration and Infrastructure

Edge Computing in Supply Chain IoT

Edge computing brings data processing closer to the point of collection, reducing latency and improving real-time decision-making capabilities. In supply chain applications, edge devices can process sensor data locally and trigger immediate responses without waiting for cloud-based analysis.

Benefits of edge computing include:

- Reduced Latency: Faster response times for critical decisions

- Improved Reliability: Continued operation even with intermittent connectivity

- Bandwidth Optimization: Processing data locally reduces network traffic

- Enhanced Security: Sensitive data can be processed without leaving the local environment

Cloud Platform Integration

Cloud platforms serve as the central nervous system for Industrial IoT supply chain implementations. These platforms aggregate data from multiple sources, provide analytics capabilities, and enable integration with existing enterprise systems.

Leading cloud platforms offer:

- Scalable Infrastructure: Ability to handle growing data volumes

- Advanced Analytics: Machine learning and AI capabilities

- API Integration: Seamless connection with existing systems

- Security Features: Enterprise-grade data protection and compliance

Blockchain Integration

The integration of blockchain technology with Industrial IoT creates immutable records of supply chain transactions and movements. This combination enhances traceability, reduces fraud, and improves trust between supply chain partners.

Applications include:

- Smart Contracts: Automated execution of agreements based on IoT data

- Provenance Tracking: Verified product origin and authenticity

- Payment Automation: Automatic payments triggered by delivery confirmation

- Compliance Documentation: Tamper-proof regulatory records

Overcoming Implementation Challenges

Data Security and Privacy Concerns

Industrial IoT implementations generate vast amounts of sensitive data that require robust security measures. Organizations must implement comprehensive cybersecurity strategies to protect against data breaches and system vulnerabilities.

Key security considerations include:

- Data Encryption: Protecting data both in transit and at rest

- Access Controls: Limiting system access to authorized personnel

- Network Segmentation: Isolating IoT networks from critical systems

- Regular Updates: Maintaining current security patches and firmware

Integration with Legacy Systems

Many organizations face challenges integrating new Industrial IoT solutions with existing legacy systems. Successful implementations require careful planning and often involve gradual migration strategies.

Strategies for successful integration include:

- API Development: Creating interfaces between new and existing systems

- Phased Implementation: Gradual rollout to minimize disruption

- Data Standardization: Ensuring consistent data formats across systems

- Staff Training: Preparing personnel for new technologies and processes

Cost-Benefit Analysis

While Industrial IoT implementations require significant upfront investment, the long-term benefits often justify the costs. Organizations should conduct thorough cost-benefit analyses to identify the most valuable use cases.

Factors to consider include:

- Initial Hardware Costs: Sensors, tags, and infrastructure requirements

- Software Licensing: Platform and analytics software expenses

- Implementation Services: Professional services for deployment and training

- Ongoing Maintenance: Support and system maintenance costs

- Return on Investment: Quantifiable benefits from improved efficiency and visibility

Future Trends and Emerging Technologies

5G Connectivity Impact

The rollout of 5G networks will significantly enhance Industrial IoT capabilities by providing faster data transmission, lower latency, and support for more connected devices. This improved connectivity will enable new applications and enhanced real-time capabilities.

Expected benefits include:

- Ultra-Low Latency: Near-instantaneous data transmission for critical applications

- Massive Device Connectivity: Support for thousands of devices per square kilometer

- Enhanced Reliability: More stable connections for mission-critical applications

- Improved Battery Life: More efficient communication protocols

Artificial Intelligence and Machine Learning Advancement

As AI and machine learning technologies continue to advance, Industrial IoT systems will become increasingly intelligent and autonomous. Future systems will be capable of self-optimization and predictive decision-making with minimal human intervention.

Emerging capabilities include:

- Autonomous Optimization: Self-adjusting systems that optimize performance automatically

- Advanced Predictive Analytics: More accurate forecasting and risk assessment

- Natural Language Processing: Voice-activated control and reporting systems

- Computer Vision: Visual inspection and quality control automation

Digital Twin Technology

Digital twin technology creates virtual replicas of physical supply chain assets and processes, enabling simulation and optimization without disrupting actual operations. This technology will become increasingly important for supply chain planning and risk management.

Applications include:

- Process Simulation: Testing changes in virtual environments before implementation

- Scenario Planning: Evaluating different strategies and their potential outcomes

- Predictive Modeling: Advanced forecasting based on virtual replicas

- Training and Education: Safe environments for staff training and development

Measuring Success and ROI

Key Performance Indicators

Organizations implementing Industrial IoT solutions should establish clear KPIs to measure success and demonstrate return on investment. Common metrics include:

- Inventory Accuracy: Percentage improvement in stock level accuracy

- Order Fulfillment Time: Reduction in time from order to delivery

- Asset Utilization: Improvement in equipment and vehicle utilization rates

- Quality Metrics: Reduction in defects and returns

- Cost Savings: Quantifiable reductions in operational costs

Long-term Value Creation

Beyond immediate operational improvements, Industrial IoT implementations create long-term value through:

- Enhanced Customer Satisfaction: Improved delivery reliability and transparency

- Competitive Advantage: Differentiation through superior supply chain capabilities

- Risk Mitigation: Better preparedness for disruptions and challenges

- Innovation Enablement: Foundation for future technology adoption and innovation

Best Practices for Implementation

Strategic Planning and Roadmap Development

Successful Industrial IoT implementations require careful strategic planning and phased rollout approaches. Organizations should develop comprehensive roadmaps that align with business objectives and available resources.

Key planning considerations include:

- Use Case Prioritization: Identifying high-value applications for initial implementation

- Technology Selection: Choosing appropriate sensors, platforms, and integration tools

- Stakeholder Engagement: Ensuring buy-in from all affected departments and personnel

- Change Management: Preparing the organization for new processes and technologies

Vendor Selection and Partnership Strategy

Choosing the right technology vendors and implementation partners is critical for success. Organizations should evaluate potential partners based on:

- Technical Expertise: Proven experience in Industrial IoT implementations

- Industry Knowledge: Understanding of specific sector requirements and challenges

- Support Capabilities: Ongoing support and maintenance services

- Scalability: Ability to grow with the organization’s needs

Popular platforms and solutions include Microsoft Azure IoT, which provides comprehensive cloud-based IoT services, and AWS IoT Core, offering scalable device connectivity and management capabilities.

Conclusion

Industrial IoT is fundamentally transforming supply chain management by providing unprecedented visibility, control, and intelligence across all aspects of operations. From real-time tracking and RFID technology to predictive analytics and smart manufacturing, these technologies are enabling organizations to create more efficient, responsive, and resilient supply chains.

The integration of IoT sensors, GPS tracking, and cloud platforms is delivering measurable improvements in inventory accuracy, operational efficiency, and customer satisfaction. As we move toward Supply Chain 4.0, organizations that embrace these technologies will gain significant competitive advantages, while those that resist change risk being left behind in an increasingly connected and intelligent business environment.