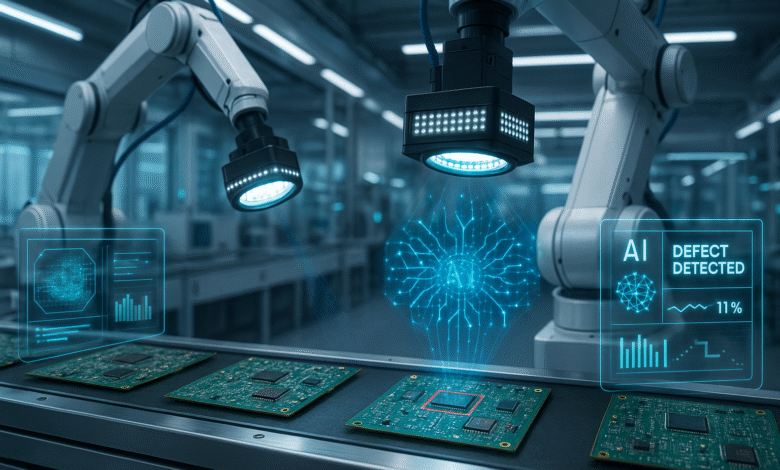

The manufacturing industry stands at a pivotal moment where traditional quality control methods are being transformed by artificial intelligence and computer vision technologies. AI visual inspection has emerged as a game-changing solution that addresses the limitations of manual inspection processes, delivering unprecedented accuracy and efficiency in defect detection and quality control.

For decades, manufacturers relied heavily on human inspectors to identify product defects, but this approach faced significant challenges including inconsistency, fatigue-related errors, and scalability issues. Traditional machine vision systems, while better than manual inspection, struggled with complex variations and required extensive programming for each application. Today’s AI-powered visual inspection systems leverage deep learning algorithms and convolutional neural networks to revolutionize how we approach manufacturing quality assurance.

The impact of AI visual inspection extends far beyond simple automation. These intelligent systems can detect subtle defects that human eyes might miss, operate continuously without fatigue, and provide consistent results across different production environments. Modern AI inspection systems achieve detection rates exceeding 99% while significantly reducing false positives, making them indispensable tools for maintaining product quality in today’s competitive manufacturing landscape.

Understanding AI Visual Inspection Technology

What Makes AI Visual Inspection Different

AI visual inspection represents a fundamental shift from rule-based machine vision to learning-based systems. Unlike traditional approaches that rely on pre-programmed criteria, AI inspection systems use deep learning to understand what constitutes normal and defective products by analyzing thousands of example images.

The core technology behind modern AI visual inspection includes convolutional neural networks (CNNs), which excel at recognizing patterns and features in visual data. These networks can identify defects ranging from surface scratches and dents to complex anomalies that would challenge even experienced human inspectors. The computer vision algorithms continuously improve their accuracy through exposure to new data, making them increasingly effective over time.

Machine learning algorithms enable these systems to adapt to new product variations without requiring extensive reprogramming. This flexibility makes AI-powered inspection particularly valuable for manufacturers dealing with diverse product lines or frequent design changes. Recent research in computer vision-based defect detection systems demonstrates the significant improvements possible when combining traditional machine vision with advanced AI techniques.

Key Components of AI Visual Inspection Systems

Modern AI visual inspection platforms integrate several critical components:

- High-resolution imaging systems capable of capturing minute details

- Edge computing hardware for real-time processing

- Deep learning models trained on extensive datasets

- User-friendly interfaces that allow non-experts to operate the systems

- Integration capabilities with existing manufacturing execution systems

The combination of these elements creates automated inspection systems that can operate autonomously while providing detailed analytics and insights about production quality trends.

Applications Across Manufacturing Industries

Automotive Manufacturing

The automotive industry has been an early adopter of AI visual inspection technology, implementing systems across multiple production stages. Computer vision systems inspect paint finishes, detect welding defects, and identify surface imperfections on body panels with remarkable precision.

AI inspection systems in automotive manufacturing can simultaneously check for multiple defect types including scratches, dents, color variations, and dimensional inconsistencies. These systems have proven particularly valuable in engine component inspection, where defect detection accuracy directly impacts vehicle safety and reliability.

Electronics and Semiconductor Production

Visual inspection in electronics manufacturing requires detecting extremely small defects on printed circuit boards, semiconductor wafers, and component assemblies. AI-powered systems excel in this environment, identifying issues like missing components, soldering defects, and microscopic cracks that traditional methods might miss.

The precision required in semiconductor manufacturing makes AI visual inspection essential for maintaining yield rates and product quality. Modern systems can inspect thousands of components per minute while maintaining detection accuracy above 99.5%.

Pharmaceutical and Medical Device Manufacturing

In pharmaceutical production, AI inspection systems verify pill integrity, check packaging completeness, and detect foreign objects in vials and containers. The machine learning algorithms can identify subtle variations in tablet appearance that might indicate formulation problems or contamination.

Medical device manufacturers rely on AI visual inspection to ensure critical components meet stringent safety standards. These systems can detect surface defects, verify assembly completeness, and check for proper labeling with exceptional reliability.

Technical Implementation and Deep Learning Approaches

Supervised Learning for Defect Classification

Most AI visual inspection systems employ supervised learning approaches where neural networks are trained on labeled datasets containing examples of both acceptable and defective products. Convolutional neural networks prove particularly effective for this task, as they can automatically extract relevant features from images without manual feature engineering.

The training process involves feeding thousands of annotated images to the deep learning model, allowing it to learn the subtle patterns that distinguish good products from defective ones. Advanced techniques like transfer learning enable these systems to achieve high accuracy even with relatively small datasets.

Unsupervised Learning and Anomaly Detection

For detecting previously unseen defect types, AI inspection systems increasingly employ unsupervised learning approaches. These systems learn the characteristics of normal products and flag anything that deviates significantly from learned patterns. This anomaly detection capability proves invaluable for identifying novel defect types that weren’t present in training data.

Computer vision systems using unsupervised learning can adapt to new product variations without requiring extensive retraining, making them more flexible and cost-effective for manufacturers with diverse product lines.

Real-Time Processing and Edge Computing

Modern AI visual inspection systems leverage edge computing to process images in real-time directly on the production line. This approach reduces latency and enables immediate feedback for quality control decisions. Deep learning models optimized for edge deployment can maintain high accuracy while operating within the computational constraints of industrial environments. Studies on surface defect detection using advanced vision systems show how modern approaches can achieve detection accuracies exceeding 99% for complex industrial components.

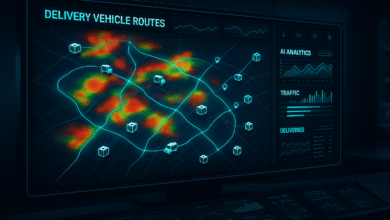

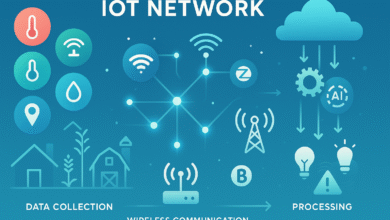

The integration of AI inspection with industrial IoT systems creates comprehensive quality monitoring networks that provide real-time insights into production performance and quality trends.

Benefits and Advantages of AI Visual Inspection

Enhanced Accuracy and Consistency

AI visual inspection systems deliver consistent performance that human inspectors cannot match. While manual inspection typically achieves 80% accuracy, AI-powered systems routinely exceed 99% detection rates. This improvement translates directly into reduced defective products reaching customers and lower warranty costs.

The consistency of automated inspection eliminates variations between different shifts, operators, and production facilities. Machine learning algorithms maintain the same high standards regardless of external factors that might affect human performance.

Cost Reduction and ROI

Implementing AI visual inspection generates significant cost savings through multiple channels:

- Reduced labor costs for quality inspection

- Lower scrap and rework expenses

- Decreased warranty claims and returns

- Improved overall equipment effectiveness (OEE)

- Faster time-to-market for new products

Many manufacturers report return on investment within 12-18 months of implementing AI inspection systems, with ongoing benefits continuing to accumulate over time.

Scalability and Flexibility

AI-powered inspection systems scale easily across production lines and facilities. Once trained on a particular product type, deep learning models can be deployed across multiple locations with minimal additional configuration. This scalability makes AI visual inspection particularly attractive for large manufacturers with global operations.

The flexibility of modern computer vision systems allows them to handle product variations and new designs without extensive reprogramming, reducing the total cost of ownership compared to traditional machine vision approaches.

Data-Driven Quality Insights

AI inspection systems generate valuable data that extends beyond simple pass/fail decisions. These systems provide detailed analytics about defect patterns, quality trends, and process variations that help manufacturers optimize their production processes.

The machine learning algorithms can identify correlations between defect types and process parameters, enabling predictive maintenance and proactive quality management. This data-driven approach transforms quality control from a reactive function to a strategic advantage.

Challenges and Considerations

Data Quality and Training Requirements

Successful AI visual inspection implementation requires high-quality training data that accurately represents the full range of products and defect types. Collecting and labeling this data can be time-consuming and expensive, particularly for complex products or rare defect types.

Deep learning models perform best when trained on diverse, representative datasets. Manufacturers must carefully consider data collection strategies and may need to generate synthetic training data to supplement real-world examples.

Integration with Existing Systems

Implementing AI inspection systems often requires integration with existing manufacturing execution systems, quality management platforms, and production line equipment. This integration can be complex and may require significant changes to established workflows.

Successful deployment typically involves close collaboration between AI technology providers, system integrators, and manufacturing teams to ensure seamless operation within existing production environments.

Change Management and Workforce Adaptation

The introduction of AI-powered inspection systems requires careful change management to help workers adapt to new technologies and roles. Rather than replacing human workers entirely, these systems often transform job functions from manual inspection to system supervision and quality analysis.

Training programs help workers develop skills in operating and maintaining AI visual inspection systems, creating opportunities for career advancement while improving overall productivity.

Future Trends and Developments

Advanced AI Capabilities

The next generation of AI visual inspection systems will incorporate more sophisticated artificial intelligence capabilities including natural language processing for defect description, advanced pattern recognition for complex assemblies, and reinforcement learning for continuous improvement.

Computer vision technology continues advancing with improved neural network architectures that require less training data and computational resources while delivering higher accuracy. These developments will make AI inspection accessible to smaller manufacturers and more specialized applications.

Predictive Quality Management

Future AI systems will move beyond reactive defect detection to predictive quality management. By analyzing patterns in inspection data alongside process parameters, these systems will predict when quality issues are likely to occur and recommend preventive actions.

This predictive capability transforms quality control from detecting problems after they occur to preventing them entirely, significantly improving efficiency and reducing waste.

Integration with Industry 4.0

AI visual inspection will become increasingly integrated with broader Industry 4.0 initiatives, connecting with IoT sensors, enterprise resource planning systems, and supply chain management platforms. This integration creates comprehensive digital ecosystems that optimize manufacturing performance across all dimensions.

The convergence of AI inspection, robotics, and industrial automation will enable fully autonomous production systems capable of self-monitoring and self-optimization.

Implementation Best Practices

Starting with Pilot Projects

Successful AI visual inspection implementation typically begins with carefully selected pilot projects that demonstrate clear value and build organizational confidence. Choose applications with well-defined quality criteria and sufficient training data availability.

Focus on high-impact problems where AI inspection can deliver immediate benefits, such as detecting critical defects that frequently escape manual inspection or improving consistency across multiple shifts.

Data Strategy and Management

Develop comprehensive data strategies that address collection, storage, labeling, and management of training datasets. Machine learning success depends heavily on data quality, so invest in robust data infrastructure from the beginning.

Consider strategies for continuously updating training datasets as products evolve and new defect types emerge. This ongoing data management ensures AI models remain accurate and relevant over time.

Vendor Selection and Partnership

Choose AI technology vendors with proven experience in manufacturing applications and strong support capabilities. Look for solutions that offer pre-trained models for common defect types while allowing customization for specific applications.

Establish partnerships that provide ongoing support for model updates, system maintenance, and technology evolution. The AI visual inspection field evolves rapidly, making vendor support crucial for long-term success.

Conclusion

AI visual inspection represents a transformative technology that addresses fundamental challenges in manufacturing quality control. By combining deep learning, computer vision, and advanced analytics, these systems deliver unprecedented accuracy, consistency, and insights that drive operational excellence. The benefits extend beyond simple defect detection to encompass cost reduction, improved customer satisfaction, and data-driven process optimization. While implementation requires careful planning and investment in data infrastructure, the proven ROI and competitive advantages make AI-powered inspection systems essential tools for modern manufacturers seeking to maintain quality leadership in increasingly competitive markets. As technology continues advancing and costs decrease, AI visual inspection will become standard practice across all manufacturing sectors, fundamentally changing how we approach product quality and process optimization.