Warehouse Automation: RFID and IoT Inventory Management Systems

The modern supply chain demands speed, accuracy, and efficiency like never before. As e-commerce continues to grow and customer expectations rise, businesses are turning to warehouse automation to stay competitive. Among the most transformative technologies driving this change are Radio Frequency Identification (RFID) and Internet of Things (IoT) systems that revolutionize how companies manage their inventory.

Warehouse automation represents a fundamental shift from manual, paper-based processes to smart, connected systems that can track, monitor, and optimize inventory in real-time. This transformation isn’t just about replacing human workers with robots – it’s about creating intelligent systems that enhance human capabilities while reducing errors and increasing operational efficiency.

Understanding Warehouse Automation Technology

Warehouse automation encompasses various technologies designed to streamline operations and reduce manual intervention in storage and distribution centers. At its core, automated warehouse systems integrate hardware and software solutions to create seamless workflows that minimize human error while maximizing throughput.

The foundation of modern warehouse automation lies in intelligent inventory tracking systems that provide real-time visibility into stock levels, locations, and movement patterns. These systems use advanced sensors, scanners, and communication technologies to create a digital twin of the physical warehouse environment.

Traditional warehouses often struggle with inventory accuracy rates hovering around 65-75%, leading to stockouts, overstocking, and frustrated customers. Automated systems can achieve accuracy rates exceeding 99%, dramatically improving customer satisfaction and reducing operational costs.

Smart warehouses utilize interconnected devices that communicate continuously, sharing data about inventory status, equipment performance, and operational metrics. This connectivity enables predictive maintenance, optimized picking routes, and automated replenishment processes that keep operations running smoothly.

RFID Technology in Modern Warehouses

Radio Frequency Identification technology has emerged as a cornerstone of warehouse automation, offering significant advantages over traditional barcode systems. RFID tags contain electronically stored information that can be read from several feet away without direct line-of-sight scanning, enabling faster and more accurate inventory tracking.

Unlike barcodes that require individual scanning, RFID readers can simultaneously capture data from multiple tags within their range. This capability allows warehouse workers to scan entire pallets or shelves in seconds rather than minutes, dramatically reducing the time required for inventory counts and updates.

RFID systems operate using electromagnetic fields to automatically identify and track tags attached to inventory items. These tags can store much more information than traditional barcodes, including product details, manufacturing dates, supplier information, and handling instructions. This rich data enables more sophisticated inventory management strategies and better traceability throughout the supply chain.

The technology comes in two main varieties: passive and active RFID tags. Passive tags rely on energy from the RFID reader to transmit data, making them cost-effective for high-volume applications. Active tags contain their own power source, enabling longer read ranges and additional features like temperature monitoring or GPS tracking.

Implementation of RFID technology requires careful planning and consideration of factors such as tag placement, reader positioning, and integration with existing warehouse management systems. However, the benefits typically outweigh the initial investment, with many companies seeing return on investment within 12-24 months.

IoT Integration for Smart Inventory Management

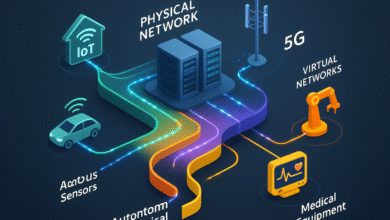

The Internet of Things transforms warehouses into intelligent ecosystems where every item, device, and process is connected and communicating. IoT sensors embedded throughout the facility continuously monitor environmental conditions, equipment status, and inventory movement, creating a comprehensive view of warehouse operations.

Smart sensors can track temperature, humidity, vibration, and other environmental factors that affect product quality and safety. For perishable goods or sensitive electronics, this monitoring capability is essential for maintaining product integrity and compliance with regulatory requirements.

IoT-enabled inventory management systems provide unprecedented visibility into stock levels and movement patterns. Smart shelves equipped with weight sensors can automatically detect when items are removed or added, updating inventory records in real-time without human intervention. This automation eliminates the need for manual cycle counts and reduces discrepancies between physical and system inventory.

Connected devices throughout the warehouse create a network of data sources that feed into centralized management platforms. These platforms use artificial intelligence and machine learning algorithms to analyze patterns, predict demand, and optimize inventory placement for maximum efficiency.

The scalability of IoT solutions makes them suitable for warehouses of all sizes. Small facilities can start with basic sensor deployments and gradually expand their IoT infrastructure as needs grow and budgets allow. Large distribution centers can implement comprehensive IoT networks that monitor thousands of data points simultaneously.

Benefits of Automated Inventory Systems

The advantages of implementing warehouse automation extend far beyond simple efficiency gains. Automated inventory systems deliver measurable improvements across multiple operational areas, creating significant competitive advantages for forward-thinking businesses.

Accuracy improvements represent one of the most immediate and impactful benefits. Manual inventory processes are prone to human error, with studies showing that traditional counting methods achieve only 65-75% accuracy rates. Automated systems consistently deliver accuracy rates exceeding 99%, virtually eliminating costly inventory discrepancies.

Labor cost reduction occurs naturally as automated systems handle routine tasks that previously required significant human resources. While automation doesn’t necessarily eliminate jobs, it allows workers to focus on higher-value activities such as problem-solving, customer service, and strategic planning rather than repetitive data entry and counting tasks.

Real-time inventory visibility enables better decision-making across the organization. Management teams can access current stock levels, identify slow-moving items, and respond quickly to supply chain disruptions. This visibility reduces safety stock requirements while maintaining service levels, freeing up working capital for other business investments.

Faster order fulfillment becomes possible when automated systems can quickly locate items, optimize picking routes, and update inventory records instantaneously. Customers receive their orders faster, leading to improved satisfaction and increased repeat business.

Enhanced traceability capabilities help companies comply with regulatory requirements and quickly respond to quality issues. When problems arise, automated systems can immediately identify affected products, their locations, and their distribution history, enabling rapid containment and resolution.

Implementation Strategies and Best Practices

Successful warehouse automation requires careful planning and phased implementation to minimize disruption while maximizing benefits. The most effective approaches begin with thorough assessment of current operations, identification of pain points, and clear definition of automation objectives.

Starting with pilot programs allows companies to test automation technologies on a small scale before committing to full deployment. These pilots provide valuable insights into system performance, integration challenges, and change management requirements that inform broader rollout strategies.

Change management represents a critical success factor that many organizations underestimate. Workers may resist new technologies due to concerns about job security or difficulty adapting to new processes. Effective change management includes comprehensive training programs, clear communication about automation benefits, and involvement of key stakeholders in the planning process.

Data quality and standardization must be addressed before implementing automated systems. Poor data quality can undermine automation benefits and create new problems. Companies should invest in data cleansing and establish standardized processes for maintaining data integrity.

Integration with existing systems requires careful planning and often custom development work. Warehouse management systems, enterprise resource planning software, and other business applications must work seamlessly with new automation technologies to realize full benefits.

Performance monitoring and continuous improvement processes ensure that automation investments deliver expected returns. Key performance indicators should be established before implementation and regularly reviewed to identify opportunities for optimization and expansion.

Cost Analysis and Return on Investment

Understanding the financial implications of warehouse automation helps justify investments and guide technology selection decisions. While initial costs can be significant, the long-term benefits typically provide compelling returns for most operations.

Hardware costs vary significantly depending on the scope and sophistication of the automation solution. RFID tags cost between $0.10 and $2.00 each, while readers range from $500 to $5,000 depending on their capabilities. IoT sensors and communication equipment add additional costs but provide expanded functionality.

Software licensing and development costs often represent the largest portion of automation investments. Warehouse management systems, analytics platforms, and integration tools require ongoing licensing fees and periodic updates. Custom development work may be necessary to integrate new technologies with existing systems.

Implementation costs include project management, training, and potential operational disruptions during deployment. These costs can be minimized through careful planning and phased rollout strategies that maintain operations while new systems are being installed and tested.

Return on investment calculations should consider both direct cost savings and indirect benefits such as improved customer satisfaction and inventory optimization. Most companies achieve payback periods between 18 and 36 months, with ongoing benefits continuing for years after initial implementation.

The total cost of ownership includes ongoing maintenance, support, and technology refresh costs. While these costs should be factored into investment decisions, they are typically offset by continued operational improvements and competitive advantages.

Future Trends in Warehouse Automation

The warehouse automation landscape continues to evolve rapidly, driven by advances in artificial intelligence, robotics, and communication technologies. Understanding these trends helps companies make informed investment decisions and prepare for future developments.

Artificial intelligence and machine learning are becoming increasingly sophisticated, enabling predictive analytics that can forecast demand, optimize inventory levels, and identify potential problems before they occur. These capabilities will continue to improve as algorithms become more advanced and data sets grow larger.

Edge computing brings processing power closer to data sources, reducing latency and enabling real-time decision-making. This trend is particularly important for warehouse automation applications that require immediate responses to changing conditions.

5G wireless technology promises to revolutionize IoT connectivity with faster speeds, lower latency, and support for many more connected devices. This enhanced connectivity will enable new automation applications and improve the performance of existing systems.

Autonomous mobile robots are becoming more capable and cost-effective, handling an increasing range of warehouse tasks including picking, packing, and transportation. These robots will work alongside human workers, creating collaborative environments that leverage the strengths of both.

Digital twin technology creates virtual replicas of physical warehouse operations, enabling simulation and optimization without disrupting actual operations. These digital models will become increasingly sophisticated, supporting advanced planning and what-if analysis capabilities.

Security Considerations for Connected Warehouses

As warehouses become more connected and automated, cybersecurity becomes increasingly important. Automated systems create new attack vectors that malicious actors might exploit to disrupt operations or steal sensitive information.

Network security must be designed from the ground up, with proper segmentation, encryption, and access controls. IoT devices and RFID systems should be isolated from critical business networks to prevent lateral movement of potential attackers.

Data protection measures ensure that sensitive inventory and operational information remains confidential. This includes encryption of data both at rest and in transit, as well as proper access controls that limit who can view and modify critical information.

Physical security remains important even in automated environments. RFID tags and IoT devices can be tampered with or replaced, potentially compromising data integrity. Regular audits and monitoring systems can help detect and prevent such attacks.

Backup and recovery procedures must account for automated systems and the data they generate. Regular testing of backup systems ensures that operations can be quickly restored in the event of system failures or cyberattacks.

Overcoming Common Implementation Challenges

Warehouse automation projects face several common challenges that can derail implementation efforts. Understanding these challenges and preparing mitigation strategies improves the likelihood of successful deployment.

Legacy system integration often proves more complex and expensive than anticipated. Older warehouse management systems may lack modern APIs or require custom development work to connect with new automation technologies. Thorough system assessments before implementation help identify and budget for these requirements.

Staff resistance to change can undermine automation efforts if not properly addressed. Workers may fear job losses or struggle to adapt to new technologies. Comprehensive training programs and clear communication about automation benefits help overcome these challenges.

Technology reliability concerns are valid, especially for mission-critical warehouse operations. Automated systems must be designed with appropriate redundancy and failover capabilities to maintain operations when components fail. Regular maintenance and proactive monitoring help prevent unexpected downtime.

Scalability limitations can emerge as businesses grow or operational requirements change. Automation solutions should be designed with future expansion in mind, using modular architectures that can accommodate additional capacity and functionality.

Vendor selection mistakes can have long-lasting consequences. Choosing partners based solely on price often leads to problems with system performance, support quality, and future upgrades. Thorough evaluation of vendor capabilities, references, and long-term viability helps ensure successful partnerships.

Measuring Success and Optimizing Performance

Successful warehouse automation requires ongoing measurement and optimization to ensure that systems deliver expected benefits and continue to improve over time. Establishing the right metrics and monitoring processes is essential for long-term success.

Key performance indicators should be established before implementation and regularly tracked to measure progress. Common metrics include inventory accuracy rates, order fulfillment speed, labor productivity, and system uptime. These metrics provide objective measures of automation success and identify areas for improvement.

Regular system audits help identify optimization opportunities and ensure that automated processes are working as designed. These audits should examine both technical performance and operational procedures to identify gaps and inefficiencies.

Continuous improvement programs encourage ongoing refinement of automated systems and processes. Regular reviews with key stakeholders can identify new requirements, technology updates, and operational enhancements that further improve performance.

Performance benchmarking against industry standards and best practices provides context for internal metrics and identifies areas where additional improvements may be possible. This benchmarking helps companies understand their competitive position and set realistic improvement targets.

Conclusion

Warehouse automation through RFID and IoT technologies represents a fundamental shift in how companies manage their inventory and operations. These systems deliver significant improvements in accuracy, efficiency, and visibility while reducing costs and enhancing customer satisfaction.

The journey toward warehouse automation requires careful planning, phased implementation, and ongoing optimization to realize full benefits. Companies that approach automation strategically, with proper attention to change management and system integration, typically achieve strong returns on their investments.

As technology continues to advance, warehouse automation will become even more sophisticated and accessible. Organizations that begin their automation journey now will be better positioned to leverage future innovations and maintain competitive advantages in an increasingly demanding marketplace.

The key to successful warehouse automation lies in starting with clear objectives, selecting appropriate technologies, and maintaining focus on continuous improvement. With proper planning and execution, RFID and IoT-enabled inventory management systems can transform warehouse operations and deliver lasting business value.