IoT and Digital Twins: Business Use Cases in Germany [2025 Insight]

In this article, we’ll explore how IoT and digital twins are being deployed in real-world business scenarios in Germany and why they’re considered game changers for efficiency, productivity, and innovation.

The convergence of the Internet of Things (IoT) and digital twins is no longer a futuristic vision—it’s the reality powering Germany’s Fourth Industrial Revolution. Known globally for its strong industrial backbone, Germany is leading the charge in adopting these technologies across diverse sectors such as manufacturing, logistics, energy, and healthcare. In this article, we’ll explore how IoT and digital twins are being deployed in real-world business scenarios in Germany and why they’re considered game changers for efficiency, productivity, and innovation.

What Are IoT and Digital Twins?

IoT refers to a vast network of interconnected devices that collect and exchange data through the internet. These devices—ranging from sensors to machinery—enable real-time monitoring, predictive maintenance, and automation.

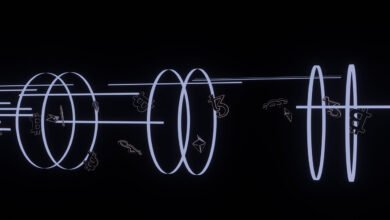

Digital twins, on the other hand, are virtual replicas of physical assets, systems, or processes. By using data from IoT devices, digital twins simulate, predict, and optimize the performance of real-world counterparts in a digital environment.

Together, IoT and digital twins enable companies to make smarter decisions, enhance productivity, reduce operational costs, and unlock new business models.

Why Germany Is at the Forefront of IoT and Digital Twin Adoption

Germany is a global leader in Industry 4.0, a national strategy focused on digitizing manufacturing and industrial operations. With a highly developed infrastructure, a robust engineering sector, and government-backed innovation hubs, German companies are uniquely positioned to embrace IoT and digital twin technologies.

Initiatives like Plattform Industrie 4.0 and funding from Fraunhofer Institutes are supporting large-scale R&D in IoT, artificial intelligence, and digital modeling technologies. This innovation-friendly ecosystem has resulted in widespread integration of IoT and digital twins into business operations.

1. IoT and Digital Twins in German Manufacturing

Germany’s manufacturing sector is a prime example of how these technologies create tangible value.

Predictive Maintenance

By integrating IoT sensors into machines and linking them with digital twins, manufacturers can detect potential failures before they happen. This not only reduces unplanned downtime but also extends machinery lifespan.

Example:

Siemens uses digital twins for real-time simulations in its factories. Data from IoT sensors help fine-tune machine operations, minimizing waste and maximizing uptime.

Product Lifecycle Management

Digital twins allow manufacturers to monitor the entire lifecycle of a product—from design and production to delivery and usage. This ensures better quality control and supports iterative improvements based on customer feedback and real-world performance.

Production Optimization

With real-time data flowing in from smart sensors, digital twins model entire production lines to identify bottlenecks or inefficiencies. This helps companies adjust workflows dynamically to maintain high throughput.

2. Smart Logistics and Supply Chain Management

Germany’s central role in European logistics makes it a hotbed for smart transportation and supply chain innovation.

Real-Time Fleet Monitoring

IoT devices installed in trucks, trains, and ships provide real-time location, temperature, and load data. Combined with digital twins, this data helps companies simulate logistics routes, optimize fuel usage, and ensure timely deliveries.

Example:

DHL Germany has adopted IoT-based tracking and digital twins to optimize warehouse operations, reducing delays and improving inventory accuracy.

Warehouse Automation

Digital twins of warehouses map every item’s location and condition. Coupled with autonomous IoT-enabled robots, German firms can automate inventory management, improving speed and accuracy.

Demand Forecasting

Digital twins analyze historical data from ERP and IoT systems to simulate supply chain responses to changes in demand. This minimizes overstocking and reduces waste.

3. Energy and Utilities: Powering Smart Grids

The energy sector in Germany, particularly amid its Energiewende (energy transition), benefits greatly from digital twins and IoT solutions.

Smart Grid Management

Digital twins simulate power grid behavior based on IoT sensor data from transformers, substations, and smart meters. This helps energy providers balance load and prevent outages.

Example:

E.ON Germany, one of the country’s largest utility providers, uses IoT data and digital twins to optimize energy distribution in real-time and reduce carbon emissions.

Renewable Energy Integration

Germany’s solar and wind infrastructure is increasingly being managed via digital twins, which model weather patterns, turbine performance, and solar output. This leads to better energy storage and grid-balancing strategies.

Asset Performance Management

IoT sensors monitor the health of energy infrastructure—like wind turbines and solar panels—feeding that data into digital twins. This enables predictive maintenance, reducing operational costs and increasing efficiency.

4. Healthcare and Medical Technology

Healthcare in Germany is undergoing a digital transformation, with IoT and digital twins playing a central role in improving patient outcomes and operational efficiency.

Personalized Patient Monitoring

Wearable IoT devices track vital signs such as heart rate, glucose levels, and activity. Digital twins of patients use this data to simulate disease progression and personalize treatments.

Example:

German hospitals like Charité Berlin are exploring digital twins for cardiac patients, simulating heart functions to better plan surgeries and medication.

Hospital Infrastructure Management

Digital twins of hospital buildings, equipment, and ventilation systems help optimize energy use and improve emergency readiness. Combined with IoT, these twins monitor air quality, temperature, and room occupancy.

Medical Equipment Optimization

Healthcare providers can track equipment usage through IoT and simulate performance using digital twins, ensuring devices are calibrated, sanitized, and available when needed.

5. Automotive Industry: Engineering the Future of Mobility

Germany’s automotive giants like BMW, Volkswagen, and Mercedes-Benz are leveraging IoT and digital twins to lead in electric and autonomous vehicle development.

Vehicle Prototyping and Testing

Digital twins simulate vehicle behavior under various road and weather conditions. With IoT data from test vehicles, engineers can tweak designs before physical production, reducing time to market.

Predictive Vehicle Maintenance

IoT sensors in vehicles send data back to manufacturers, who use digital twins to anticipate wear and tear and notify customers of service needs proactively.

Autonomous Driving

For self-driving cars, real-time IoT data from cameras, LiDAR, and GPS are fed into a digital twin of the vehicle and its environment. This helps in training AI systems and refining decision-making algorithms.

6. Smart Cities and Public Infrastructure

Several German cities are rolling out IoT and digital twins to enhance urban living and sustainability.

Traffic Flow and Mobility Planning

Digital twins of cities simulate traffic behavior using data from IoT devices like traffic lights, cameras, and smart sensors. This helps city planners reduce congestion and enhance public transport efficiency.

Building Management

Municipal buildings are modeled using digital twins to optimize lighting, heating, and space utilization, reducing carbon footprints and energy costs.

Emergency Response Simulation

Emergency services in cities like Hamburg use digital twins to simulate disaster scenarios—fires, floods, or epidemics—using real-time IoT data for better planning and quicker response.

Challenges and Considerations in Adoption

Despite the advantages, businesses in Germany face several challenges when implementing IoT and digital twins:

-

Data Security & Privacy: Strict GDPR compliance and cyber threats require robust data governance frameworks.

-

Integration Complexity: Merging legacy systems with new IoT platforms and digital models is often resource-intensive.

-

Skill Shortage: Demand for skilled professionals in data science, AI, and digital modeling exceeds supply.

Addressing these challenges will require strategic investments in upskilling, secure infrastructure, and open innovation platforms.

The Road Ahead: What’s Next for German Enterprises?

As Germany accelerates its digital transformation goals for 2030, IoT and digital twins will continue to play a critical role. Emerging trends such as edge computing, AI-driven simulation, and blockchain-based IoT authentication are expected to further strengthen the capabilities of these technologies.

Companies that invest early in integrating IoT and digital twins across their operations will be best positioned to thrive in an increasingly competitive and digital marketplace.

Final Thoughts

From smart factories to connected hospitals and predictive logistics, the synergy of IoT and digital twins is reshaping business landscapes across Germany. This convergence is not just about technology—it’s about reimagining how businesses operate, deliver value, and engage with the future.

As adoption scales, the German economy stands to benefit enormously through increased productivity, sustainability, and global competitiveness. For businesses looking to innovate and scale, embracing IoT and digital twins is no longer optional—it’s essential.