How Linear RFID Antennas Improve Tag Detection

Learn how linear RFID antennas improve tag detection with increased read range, better accuracy, and focused beam patterns. Explore benefits and applications.

In the world of RFID tag detection, choosing the right antenna can make the difference between a system that barely meets expectations and one that exceeds all requirements. Linear RFID antennas have become the go-to solution for applications where performance and accuracy matter most. Unlike their circular-polarized counterparts, linear antennas transmit electromagnetic waves in a single plane, delivering focused, directional communication that excels when tag orientation is predictable and controlled.

The advantage of linear polarized antennas extends far beyond simple read capability. These antennas provide superior read range, typically outperforming circular alternatives when tags remain properly aligned. In warehouse automation, retail inventory management, and asset tracking systems, this precision translates directly into operational efficiency and cost savings. Organizations deploying linear antenna technology report higher detection accuracy, fewer false positives, and improved overall system reliability.

Understanding how linear RFID antennas improve detection requires looking at the fundamental physics of antenna polarization, the practical benefits in real-world deployments, and the specific applications where linear technology shines. Whether you’re managing a high-speed conveyor system, tracking inventory in a controlled warehouse environment, or implementing an access control system, linear antennas offer distinct advantages that circular polarized options simply cannot match in aligned tag scenarios.

Understanding Linear RFID Antenna Technology

How Linear Polarization Works

Linear RFID antennas operate on a simple but powerful principle: they emit electromagnetic waves along a single plane, either horizontal or vertical. This focused directionality is what makes linear polarization so effective for tag detection in controlled environments. When the antenna transmits, it generates a highly directional field that propagates outward in predictable patterns, allowing for precise communication with tags positioned along that plane.

The effectiveness of this technology depends entirely on alignment. A tag that matches the antenna’s polarization plane will receive maximum signal strength and respond with optimal backscatter energy. This is why linear antenna systems excel in applications where tag orientation remains consistent—such as items moving down a conveyor belt or products positioned vertically on a shelf.

Linear vs. Circular Polarization: Key Differences

The distinction between linear polarized antennas and circular alternatives fundamentally affects system performance. Circular polarization works by combining vertical and horizontal waves with a 90-degree phase difference, creating a rotating electromagnetic field. This approach works well when tag orientation is unpredictable, but it sacrifices read range and focused detection.

Linear polarization sacrifices versatility for performance. Tags must align with the antenna’s plane to achieve optimal reading. However, when that alignment exists, linear RFID tag reading delivers substantially better range and signal strength. In environments where this alignment can be controlled—manufacturing facilities, distribution centers, and automated systems—linear technology becomes the clear winner.

Key Performance Benefits of Linear RFID Antennas

Extended Read Range and Signal Strength

One of the most compelling reasons organizations choose linear RFID antennas is the extended read range they provide compared to circular alternatives. When a tag’s antenna aligns with the reader antenna’s polarization plane, the signal coupling becomes incredibly efficient. This efficiency translates into reading distances that can exceed 15-20 meters in favorable conditions, significantly outperforming circular options in aligned scenarios.

The extended range comes from the focused beam pattern that linear antennas produce. Rather than spreading energy in all directions, a linear antenna concentrates its transmitted power along specific planes, much like a flashlight beam compared to a diffuse light bulb. This concentration of energy means tags at greater distances still receive sufficient signal to activate and respond.

For warehouse operations and logistics applications, this extended range means fewer readers needed to cover the same area, directly reducing hardware costs and system complexity. A single linear antenna can cover a longer conveyor section or warehouse aisle than multiple circular antennas, improving operational efficiency and return on investment.

Superior Tag Detection Accuracy

Linear polarized antennas dramatically reduce false positives and missed reads in controlled environments. By eliminating the ambient noise and scattered signals that circular antennas often pick up, linear technology provides cleaner, more reliable RFID tag detection. This accuracy improvement matters significantly in high-volume environments where reading errors compound quickly.

The focused beam pattern minimizes multipath interference—a common problem where signals bounce off metallic surfaces and create confusion in the read zone. When your antenna transmits in a single, controlled plane, these reflections become far less problematic. Tags within the primary beam path read reliably, while stray signals are largely ignored.

In retail environments managing inventory, this accuracy means better stock counts and fewer costly scanning errors. In manufacturing, it means higher first-pass read rates on production lines. Organizations implementing linear antenna systems typically report read accuracy improvements of 10-20 percent compared to circular alternatives in aligned-tag applications.

Reduced Electromagnetic Interference

Linear RFID antenna systems prove remarkably resistant to environmental electromagnetic noise. Since they operate with focused, directional signals, they’re less susceptible to interference from nearby metallic objects, electrical equipment, and other RFID systems operating in adjacent zones.

Circular antennas, by contrast, capture signals from all directions, which means they’re more vulnerable to cross-talk from other readers and ambient RF noise. In densely-populated warehouse environments with multiple readers operating simultaneously, this susceptibility creates real problems. Linear antenna technology mitigates these issues naturally through its directional characteristics.

For facilities with tight spacing between reading zones—such as retail checkout areas or warehouse receiving docks—linear antennas allow you to place readers closer together without experiencing the cross-interference that would plague a circular antenna deployment. This capability makes linear technology essential for high-density reading applications.

Real-World Applications of Linear RFID Antennas

Warehouse and Distribution Center Operations

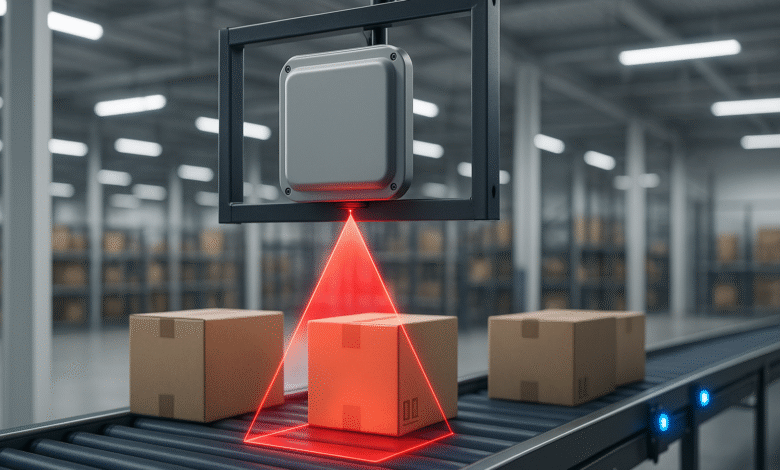

Warehouse automation relies heavily on linear RFID antenna technology because tags on boxes and pallets typically maintain predictable, controlled orientations. As items move through conveyors and sorting systems, their position relative to reading gates remains consistent. This makes linear antennas ideal for achieving the 99 percent read rates that modern logistics demand.

Distribution centers deploying linear antenna systems at receiving docks, shipping areas, and internal conveyor networks experience significant improvements in throughput and accuracy. The extended read range of linear technology means fewer gate positions needed to complete comprehensive system coverage, reducing infrastructure costs while improving flow efficiency.

Many leading logistics operations use linear antennas specifically because they can achieve near-perfect read rates at standard conveyor speeds without extensive error correction protocols. This operational simplicity reduces software complexity and makes system maintenance more straightforward.

Manufacturing and Production Line Integration

On manufacturing production lines, linear RFID tag reading provides the reliable, high-speed scanning necessary for quality control and inventory tracking. Products moving along assembly lines can have tags oriented vertically, horizontally, or at fixed angles depending on the product design. Once the orientation is established, linear polarized antennas excel at maintaining consistent reads throughout the production process.

Automotive manufacturers, electronics producers, and appliance makers all rely on linear antenna systems to track components from receiving through final assembly. The focused detection capability ensures that no tagged component escapes the read zone, critical for maintaining accurate production records and material accountability.

Asset Tracking in Retail Environments

While retail often seems like a poor fit for linear antennas due to varied tag orientations, specific applications work perfectly. Shelf-mounted linear RFID antennas track product inventory on backroom shelves and storage areas where items sit in controlled positions. Gates at receiving areas and stockrooms also work well with linear technology, since merchandise enters in predictable orientations.

Retailers implementing linear antenna systems in back-of-house operations report faster inventory counts and more accurate stock visibility. The technology enables smaller stores to achieve inventory accuracy typically associated with large regional distribution centers.

Optimizing Linear RFID Antenna Performance

Proper Tag Alignment and Mounting

Achieving maximum performance from linear RFID antennas requires deliberate attention to tag placement and orientation. Tags should be mounted so their antenna aligns with the reader antenna’s polarization plane. For vertical reader antennas, mount tags vertically. For horizontal antennas, position tags horizontally.

This alignment requirement isn’t a limitation—it’s an optimization opportunity. By controlling tag orientation, you ensure every tag receives maximum signal strength, creating a reading environment where even marginal tags read reliably. Organizations that take care with tag mounting experience dramatic improvements in read rates compared to haphazard installations.

Mounting tags on non-conductive materials like cardboard, plastic, and fabric allows optimal antenna performance. Placing tags on or near metal surfaces requires special metal-compatible tags with built-in spacers to prevent signal absorption.

Selecting Appropriate Antenna Gain and Beam Width

Linear RFID antenna performance depends significantly on choosing the right gain level for your application. Higher-gain antennas (8.5-10 dBic or greater) provide extended range but narrower beam widths, ideal for focused reading zones. Lower-gain antennas offer wider beam coverage, useful for broader area applications but with reduced range.

For conveyor systems and gates, higher-gain antennas typically deliver better results. For retail environments requiring coverage across wider areas, lower-gain options might be more appropriate. Evaluate your specific reading zone dimensions and tag density before selecting antenna specifications.

Managing Multiple Antenna Deployments

When deploying multiple linear antenna systems in proximity, proper synchronization and separation become critical. Readers should be configured to operate on different time slots or frequency bands to prevent interference between adjacent antennas. Many modern RFID readers support automatic antenna switching, allowing you to coordinate multiple reading points seamlessly.

Spatial separation also helps. When possible, position linear antennas at least 1-2 meters apart to minimize cross-coupling. Physical barriers and careful cable routing reduce interference further. With proper configuration, linear antenna networks can cover extensive areas while maintaining read reliability.

Comparing Linear Antennas to Alternative Technologies

Linear vs. Circular Polarized Antennas

The choice between linear and circular polarized antennas hinges on application requirements. Circular polarization excels when tag orientation varies unpredictably—conveyor systems with randomly oriented products, mobile asset tracking, or retail shelf applications with items at multiple angles. However, circular antennas sacrifice approximately 3 dB of gain compared to linear antennas, meaning shorter effective range and reduced read reliability for aligned tags.

Linear RFID antenna technology wins decisively in applications where tag orientation can be controlled. The performance advantage is substantial enough that many organizations restructure their tagging and mounting processes specifically to enable linear antenna deployment.

Near-Field vs. Far-Field Antenna Considerations

RFID tag detection at very short distances (a few centimeters) sometimes requires special near-field antennas rather than far-field linear options. Near-field technology works through magnetic coupling rather than electromagnetic radiation, useful for embedded tag applications or proximity readers.

For most warehouse, manufacturing, and retail applications, far-field linear antennas provide better overall performance and flexibility. Near-field options remain specialized tools for specific high-security or small-scale applications.

Best Practices for Linear RFID Antenna Implementation

When deploying linear RFID antennas, success depends on attention to several implementation details:

- Conduct Site Surveys: Test antenna performance in your actual environment before full deployment. Different facilities have unique RF characteristics based on structure, materials, and existing equipment.

- Plan Tag Orientation: Document tag mounting standards and ensure consistent orientation across all tagged items. This becomes part of your operational procedure.

- Calculate Power Requirements: Ensure your RFID readers provide sufficient power to activate tags at the distances you require. Power settings interact with antenna gain to determine effective read range.

- Implement Cable Management: Use quality coaxial cables and connectors. Poor cable condition degrades antenna performance significantly.

- Configure Reader Settings: Modern readers offer numerous configuration options. Work with your RFID provider to optimize power levels, antenna sequencing, and sensitivity settings for your specific environment.

- Maintain Equipment: RFID systems require minimal maintenance, but inspect antenna connectors regularly and ensure cables remain protected from damage.

The Future of Linear RFID Technology

RFID technology continues evolving, with improvements in reader sensitivity, tag design, and antenna efficiency. Linear RFID antenna technology is benefiting from these advances just as much as circular alternatives. Next-generation readers provide better filtering capabilities, noise reduction, and more sophisticated tag classification algorithms.

Emerging phased array antenna technology promises even greater control over radiation patterns and read zones. These advanced systems maintain the linear polarization benefits while adding new capabilities for beam steering and directional focusing. As manufacturing processes improve, expect even higher performance and lower costs from linear antenna systems.

For organizations implementing RFID today, linear antenna technology represents a proven, mature approach that delivers exceptional performance in the right applications. For those considering RFID adoption, understanding when linear antennas make sense—versus when circular alternatives are necessary—is critical to system success.

Conclusion

Linear RFID antennas represent a powerful solution for tag detection in controlled environments where antenna and tag orientation can be managed consistently. By leveraging focused beam patterns and single-plane polarization, linear technology delivers superior read range, enhanced accuracy, and reduced electromagnetic interference compared to circular alternatives.

Whether implementing systems in warehouse operations, manufacturing facilities, or retail back-of-house areas, linear antennas excel when tags maintain predictable positions. Success requires attention to proper tag mounting, appropriate antenna selection based on your reading zone requirements, and careful system configuration.

For organizations seeking the performance advantages of linear polarized antenna technology, the investment in understanding and implementing these systems correctly pays dividends through improved inventory accuracy, operational efficiency, and system reliability.

Learn more about RFID technology best practices through Impinj’s comprehensive RFID guides and explore how standardized RFID frameworks from GS1 support interoperable systems to ensure your implementation aligns with industry protocols and delivers maximum value from your RFID investment.